News

Site Editor

Site

https://npcinjection.usa72.wondercdn.com/uploads/image/665ecd3983ca3.png

Injection molding machine is widely used in industries such as electronics, automobiles, healthcare, and packaging, and is an indispensable and important equipment in modern industrial production.

Site

https://npcinjection.usa72.wondercdn.com/uploads/image/665ecd3983ca3.png

Injection molding machine is widely used in industries such as electronics, automobiles, healthcare, and packaging, and is an indispensable and important equipment in modern industrial production.

Injection Molding Machine: A Magical Manufacturer of Plastic Products

Views: 1331

Author: Site Editor

Publish Time: 2024-02-27

Origin: Site

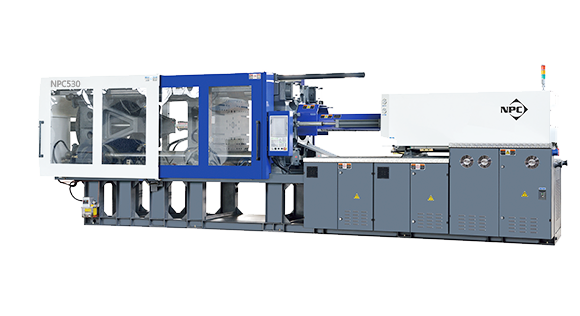

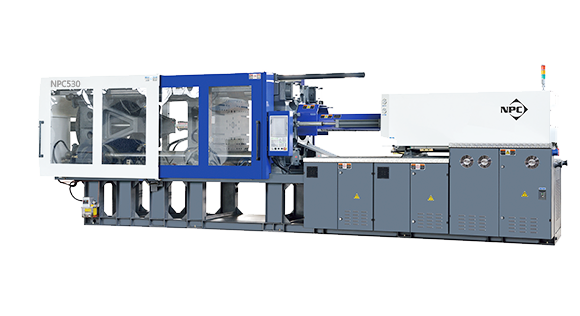

Injection molding machine, a type of molding machine that melts plastic and injects it into molds to form various plastic products, is known as the "magical maker of plastic products". It is widely used in industries such as electronics, automobiles, healthcare, and packaging, and is an indispensable and important equipment in modern industrial production.

The principle of injection molding machine

The principle of an injection molding machine is not complicated. Its core is to use screws or plungers to melt plastic, then inject it into the mold under high pressure, cool and solidify it to obtain the product.

Components of injection molding machine

An injection molding machine mainly consists of the following parts:

-

Rack: The frame that supports the entire machine, like the foundation of a house.

-

Injection device: A device that melts plastic and injects it into a mold, including screws, barrels, nozzles, etc. It is the "heart" of an injection molding machine.

-

Mold: The metal cavity used to shape plastic products is the "soul" of injection molding machines.

-

Hydraulic system: The system that provides power for the injection device and is the "muscle" of the injection molding machine.

-

Control system: The system that controls the operation of the entire machine is the "brain" of the injection molding machine.

Classification of injection molding machines

Injection molding machines can be classified according to different standards, and common classification methods include:

-

According to the type of injection device: screw injection molding machine and plunger injection molding machine.

-

According to the type of locking force: hydraulic injection molding machine, mechanical injection molding machine, and electric injection molding machine.

-

According to the molding method: horizontal injection molding machine, vertical injection molding machine, and inclined injection molding machine.

Selection of injection molding machines

Choosing a suitable injection molding machine requires considering the following factors:

-

The size and shape of the product: The size and shape of the product determine the injection volume and locking force of the injection molding machine.

-

Material of the product: The material of the product determines the material of the barrel and screw of the injection molding machine.

-

Product yield: The product yield determines the cycle time and production efficiency of the injection molding machine.

-

The budget of the enterprise: The budget of the enterprise determines the brand and model of the injection molding machine.

-

Operation and maintenance of injection molding machines

-

The operation and maintenance of injection molding machines require professional training to ensure safe production and product quality.

Application of injection molding machines

The application range of injection molding machines is very wide, covering almost all plastic products, including:

-

Electronic appliances: mobile phones, computers, televisions, etc.

-

Automobile: bumper, dashboard, interior trim, etc.

-

Medical: Medical devices, disposable medical supplies, etc.

-

Packaging: bottles, containers, packaging film, etc.

Injection molding machines are indispensable and important equipment in modern industrial production, and their development level represents the level of manufacturing industry. With the continuous progress of injection molding machine technology, it will continue to drive the development of the plastic product industry and bring more convenience to people's lives.